To ensure consistent quality, each piezo actuator undergoes thorough testing and characterization. This guarantees optimal electrical contact and efficient transfer of electrical energy into mechanical motion. Piezo Direct employs advanced bonding techniques, ensuring a strong and reliable bond between the piezoelectric layers and electrodes. The next stage involves the assembly and bonding of the piezoelectric elements to create the complete piezo actuator. The company employs specialized machinery and equipment to achieve high precision and accuracy during these manufacturing steps. This involves precise cutting, dicing, and shaping processes to create the necessary geometries and dimensions. Piezo Direct utilizes advanced fabrication techniques to shape the piezoelectric materials into the desired actuator designs. These materials are carefully sourced to ensure consistent and reliable actuator performance. The production of piezo actuators begins with the selection of premium-grade piezoelectric materials, such as lead zirconate titanate (PZT), known for its exceptional performance and durability. The manufacturing process at Piezo Direct involves state-of-the-art technologies and stringent quality control measures. Piezo Direct is a leading manufacturer of piezo actuators, specializing in the production of high-quality and reliable piezoelectric devices. Their compact size and ability to operate in harsh environments also contribute to their popularity in various industries and research fields.

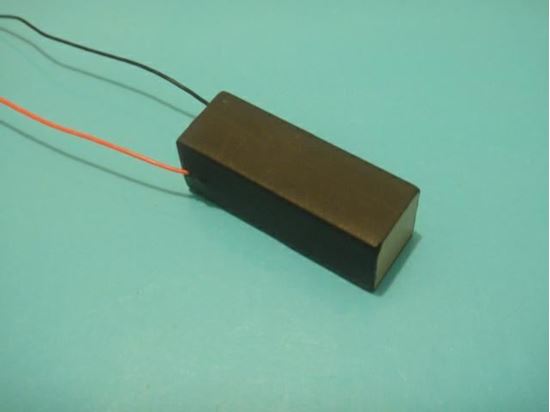

Piezo stack actuators are known for their high precision, fast response times, and high force output, making them suitable for applications such as nanopositioning, precision machining, valve control, and active vibration damping. The movement can be in the form of linear motion, rotary motion, or even flexural motion, depending on the design and configuration of the actuator. When a voltage is applied to the electrodes, the piezoelectric layers expand or contract, causing the actuator to move. This type of actuator consists of multiple layers of piezoelectric material stacked together and sandwiched between electrodes. One example of a piezoelectric actuator is the piezo stack actuator. Piezo actuators are widely utilized across many industries, including medical, industrial, commercial, machinery, automotive, and aerospace. For these reasons, they are best suited for applications requiring precise movement, for example in motors and a growing variety of other practical uses.

There are virtually no moving parts and they are quite reliable. Piezoelectric actuators are very simple in design with little to no maintenance or lubrication required.

There are multiple types of actuators that suit different needs based on their unique properties. Piezo actuators are used for their precise control and efficiency in a wide variety of applications, with precision down to the micrometer. Piezoelectric actuators utilize the inverse piezoelectric effect to generate physical displacement in response to an electrical input. The purpose of an actuator is to convert electrical energy into mechanical energy.

0 kommentar(er)

0 kommentar(er)